Farsamada Daaweynta Dhulka ee Daawaha Aluminium

Farsamada Daaweynta Dhulka ee Daawaha Aluminium

|

Aluminiumku wuxuu leeyahay faa'iidooyin badan sida cufnaanta hoose, xoog gaar ah oo sarreeya, caabbinta daxalka wanaagsan, korantada sare iyo kuleylka kuleylka, alxanka, caagagga wanaagsan, farsamaynta fudud iyo sameynta, iyo guryaha qurxinta dusha sare. Daawaha aluminiumku waxa uu ka samaysan yahay aluminium saafi ah iyada oo lagu daray qaar ka mid ah walxaha alloying. Aluminiumka aluminiumku wuu ka fiican yahay aluminium saafi ah. Sababtoo ah dabeecadda firfircoon ee aluminiumka, waxay si kedis ah u samayn kartaa filimka amorphous oxide ee hawada, taas oo ka dhigaysa iska caabbinta daxalka ee jawiga, laakiin dhumucda filimku waa kaliya 4nm, qaab-dhismeedkuna waa dabacsan, dhuuban oo dhuuban. Dabada, adkaanta hooseeya, caabbinta liidata, iyo xoogga farsamada hooseeya, sidaas darteed waxaa lagama maarmaan ah in gacanta lagu daboolo dusha aluminium filim si loo gaaro ujeedada ilaalinta. Caadi ahaan waxaa lagu gaari karaa daawaynta oksaydhka, korantada, iyo dahaarka dibadda. |

1 Daaweynta Oxidation

Daawaynta oksaydhisku waxay u badan tahay oxidation anodic, oksaydhaynta kiimikaad, iyo oksaydhaynta micro-arc. Xu Lingyun iyo al. [1] wuxuu bartay sifooyinka farsamada iyo iska caabbinta daxalka ee A356 aluminium aluminium iyagoo fulinaya seddex kala duwan daaweynta dushas: oksidation kiimikaad, anodization iyo oksidation micro-arc. Iyada oo loo marayo tignoolajiyada SEM, xidho tijaabada iska caabinta daxalka, qaab-dhismeedka dusha sare, dhumucda lakabka oksaydhka, xidhashada caabbinta iyo iska caabinta daxalka ee aluminium aluminium ka dib saddex daaweynta dushas ayaa la falanqeeyay oo si faahfaahsan loo barbardhigay. Natiijadu waxay muujinaysaa in ka dib kala duwan daaweynta dushas, dusha daawaha aluminiumku waxay samayn karaan filimo oksaydh ah oo dhumucyo kala duwan leh, adkaanta dusha iyo xidhashada iska caabbinta si weyn ayaa loo wanaajiyey, caabbinta daxalka ee daawaha ayaa sidoo kale loo wanaajiyey heerar kala duwan. Marka la eego waxqabadka guud, oxidation micro-arc way ka fiican tahay oxidation anodic, iyo oxidation anodic way ka fiican tahay oksaydhka kiimikada.

1.1 Anodizing

Anodizing sidoo kale waxaa loo yaqaan oxidation electrolytic, taas oo asal ahaan ah daawaynta oksaydhka korantada. Waxay u isticmaashaa aluminium iyo aluminium aluminium sida anodes ee unugga elektaroonigga ah, iyo filim oxide ah (badanaa lakabka Al 2 O 3) ayaa laga sameeyay dusha aluminiumka ka dib marka la shido. Filimka oksaydhka ah ee laga helo oxidation anodic wuxuu leeyahay iska caabin wanaagsan oo daxalka, habka xasiloon iyo dhiirigelin sahlan. Waa habka ugu aasaasiga ah uguna caansan daaweynta dusha sare ee aluminium iyo aluminium aluminium ee casriga ah ee dalkayga. Filimka 'anodic oxide' wuxuu leeyahay sifooyin badan: lakabka xannibaadda ee filimka oksaydhku wuxuu leeyahay qallafsanaan sare, caabbinta xirashada wanaagsan, caabbinta daxalka wanaagsan, walxaha dahsoon ee wanaagsan, xasilloonida kiimikada sare, waxaana loo isticmaali karaa sida filimka saldhigga ah ee daboolka; filimka oksaydhku wuxuu leeyahay godad badan oo pinholo ah waxaana loo isticmaali karaa waxaa loo isticmaalaa midabaynta iyo midabaynta kala duwan si loo kordhiyo waxqabadka qurxinta ee dusha aluminium; dhaqdhaqaaqa kulaylka ee filimka oksaydhku aad ayuu u hooseeyaa, waana dahaarka kulaylka wanaagsan iyo lakabka ilaalinta kulaylka. Si kastaba ha ahaatee, oksaydhka anodic-ka ee aluminiumka iyo aluminiumyada aluminiumku waxay inta badan isticmaalaan chromate sida oksidat-ka, taas oo keenta wasakhowga deegaanka ee weyn.

Cilmi-baarista hadda jirta ee anodizing ee aluminium iyo aluminium aluminium, fiiro gaar ah ayaa sidoo kale la bixiyaa si loo isticmaalo sifooyinka ions birta qaarkood si loo hagaajiyo sifooyinka aluminium iyo aluminium aluminium. Tusaale ahaan, Tian Lianpeng [2] waxay adeegsatay tignoolajiyada implantation ion si ay ugu durto titanium dusheeda aluminium alloy, ka dibna waxay sii samaysay anodization si ay u hesho lakabka aluminium-titanium-ka isku dhafan ee filimka anodized, kaas oo ka dhigay dusha filimka anodized mid siman oo lebis ah. , iyo hagaajinta anodization ee daawaha aluminium. Cufnaanta filimka; Maqaarka ion titanium wuxuu si weyn u wanaajin karaa iska caabbinta daxalka ee aluminium aluminium aluminium aluminium oxide film acid iyo alkaline NaCl xalalka, laakiin ma saameynayso qaab dhismeedka amorphous ee aluminium aluminium aluminium oxide film. Gelitaanka ion nickelku wuxuu ka dhigayaa qaab-dhismeedka dusha sare iyo qaab-dhismeedka aluminiumka aluminium oxide-ka ah ee cufan iyo labis. Nikkelka la duray wuxuu u jiraa qaab nikkel bir ah iyo nikkel oxide oo ku jira aluminium alloy anodic oxide filim.

1.2 oksidation kiimikaad

Oksijiinta kiimikada waxaa loola jeedaa habka daahan kaas oo dusha sare ee aluminiumka nadiifka ah uu la falgalo oksijiinta ee xalka oksijiinta iyada oo loo marayo ficil kiimiko ah oo hoos yimaada xaaladaha heerkulka qaarkood si loo sameeyo filim cufan. Waxaa jira habab badan oo oksaydheyn kiimiko ah oo loogu talagalay aluminium iyo aluminium aluminium, marka loo eego dabeecadda xalka

Waxaa loo qaybin karaa alkaline iyo acidic. Sida laga soo xigtay dabeecadda filimka, waxaa loo qaybin karaa filimka oxide, filimka fosfatetada, filimka chromate iyo filimka chromic acid-phosphate. Filimka oksaydhka ah ee laga helay oxidation kiimikaad ee aluminium iyo aluminium qaybo aluminium ah ayaa dhumucdiisu tahay 0.5 ~ 4μm. Waxay leedahay iska caabbinta xidhashada liidata iyo iska caabbinta daxalka ka hooseeya filimka anodic oxide. Kuma habboona in keligiis la isticmaalo, laakiin waxay leedahay iska caabin daxalka qaarkood iyo astaamo jireed oo wanaagsan. Awoodda nuugista ayaa ah asal wanaagsan oo rinjiyeynta. Rinjiga ka dib oksaydhka kiimikaad ee aluminium iyo aluminium aluminium waxay si weyn u wanaajin kartaa xoogga isku xidhka u dhexeeya substrate-ka iyo daahan, waxayna kor u qaadi kartaa iska caabbinta daxalka aluminium [3].

1.3 Habka oksidation Micro-arc

Tiknoolajiyada oksaydhka ee micro-arc waxaa sidoo kale loo yaqaannaa tignoolajiyada oksaydhka micro-plasma ama tignoolajiyada dhigaalka dhinbiiciga ah ee anode, taas oo ah nooc ka mid ah korriinka goobta dhexdeeda iyada oo loo marayo dheecaanka micro-plasma ee dusha sare ee birta iyo alloyskeeda. Oxidation

Farsamada cusub ee xuubka dhoobada. Filimka dusha sare ee ay samaysay tignoolajiyadani waxa uu leeyahay xoog isku xidhan oo xoog leh oo leh substrate-ka, adkaanta sare, xidhashada caabbinta, iska caabinta daxalka, caabbinta shoogga kulaylka sare, dahaarka korantada wanaagsan ee filimka, iyo danab burbursan oo sarreeya. Ma aha oo kaliya, tiknoolijiyada waxay qabataa habka kuleylka sare ee micro plasma arc kuleylinta cufnaanta tamarta aad u sareysa, qaab dhismeedka matrixka ma saameynayo, geeddi-socodka ma aha mid adag, oo ma keeno wasakhowga deegaanka. Waa tignoolajiyada daawaynta dusha shay cusub oo rajo leh. Waxay noqonaysaa goob cilmi baaris ah oo ku taal berrinka tignoolajiyada injineernimada dusha sare ee alaabta. Zhang Juguo iyo al.

Isticmaalo aluminium ka shaqeynaya alloy LY12 sida walxaha tijaabada ah, loo isticmaalo MAO240/750 qalabka oxidation micro-arc, TT260 dhumucda dhumucda iyo AMARY-1000B mikroskoob elektaroonik ah si ay u bartaan saamaynta danab arc, cufnaanta hadda iyo oksaydhka wakhtiga lakabka dhoobada. Saamaynta waxqabadka. Iyada oo loo marayo tijaabooyin taxane ah oo aluminium alloy micro-arc oxidation ah oo tijaabo ah oo leh Na 2 SiO 3 electrolyte, sharciga kobaca ee filimka oxide dhoobada inta lagu jiro geeddi-socodka oxidation micro-arc iyo saamaynta kala duwan ee ka kooban electrolyte iyo xoojinta tayada dhoobada dhoobada filimada waa la bartay. Oxidation-ka micro-arc ee dusha aluminium aluminium waa nidaam aad u adag, oo ay ku jiraan samaynta korantada ee filimka hore ee oksaydhka, iyo burburka soo socda ee filimka dhoobada, kaas oo ay ku jiraan saameynta jireed ee thermochemistry, electrochemistry, iftiinka, korontada, iyo kulaylka. .

Nidaamku wuxuu saameeyaa walxaha substrate-ka laftiisa, xuduudaha sahayda korantada, iyo cabbirada elektrolytka, wayna adagtahay in lala socdo onlaynka, taas oo keeneysa dhibaatooyinka cilmi-baarista aragtida. Sidaa darteed, ilaa hadda, ma jiro qaab aragtiyeed oo si qancin kara u sharxi kara dhacdooyin kala duwan oo tijaabo ah, cilmi-baadhista habkeedana weli waxay u baahan tahay sahan iyo horumarin dheeraad ah.

2 Electroplating iyo dahaadhay kiimikaad

Electroplating waa in lagu shubo lakabka birta kale ee dusha sare ee aluminium iyo aluminium aluminium iyadoo la isticmaalayo habab kiimiko ama kiimiko kiimiko ah, taas oo bedeli karta sifooyinka jireed ama kiimikaad ee dusha aluminium aluminium. dusha sare

Hab-dhaqanka; naxaasta, nikkel ama dahaarka daasadda waxay hagaajin karaan alxanka daawaha aluminium; iyo daasad-kulul-kulul ama aluminium-tisaabka aluminiumku waxay hagaajin kartaa dufanka aluminium aluminium; guud ahaan hagaajinta engegnaanta dusha oo xidho caabbinta aluminium aluminium oo leh dhejis chromium ama dhejis nikkel ah; Ku darista Chrome ama nikkel waxay sidoo kale hagaajin kartaa qurxinta. Aluminiumka waxaa lagu dahaadhi karaa electrolyte si loo sameeyo dahaar, laakiin daahan waa sahlan tahay in la fujiyo. Si loo xalliyo dhibaatadan, aluminium waa la dhigi karaa oo lagu dahaadhay xal aqueous ah oo ka kooban iskudar zinc ah. Lakabka immersion-ka ee zinc waa in la isku xiro aluminiumka iyo matrix-yada aluminiumka ah iyo dahaarka xiga. Buundada muhiimka ah, Feng Shaobin et al. [7] wuxuu bartay codsiga iyo habka lakabka immersion ee zinc ee substrate aluminium, waxayna soo bandhigtay tignoolajiyada ugu dambeeyay iyo codsiga habka immersion zinc. Electroplating ka dib immersion in zinc sidoo kale samayn kartaa filim dalool khafiif ah dusha aluminium ka dibna electroplating.

Plating Electroless waxaa loola jeedaa tignoolajiyada samaynta filimada kaas oo daahan birta ah lagu shubo birta oogada sare ee falcelinta kiimikada autocatalytic ee xal la wada nool milix bir ah iyo walax yaraynaysa. Waxaa ka mid ah, kuwa ugu badan ee loo isticmaalo waa dahaarka aluminium ee Ni-P. Marka la barbardhigo habka korantada, dhejinta korantada waa a

Nidaam wasakhaysan oo aad u hooseeya, daawaha Ni-P ee la helay ayaa ah beddel wanaagsan oo lagu dhejiyo chromium. Si kastaba ha ahaatee, waxaa jira qalabyo badan oo habka loogu talagalay dhejinta elektiroonigga ah, isticmaalka maaddadu waa weyn tahay, waqtiga hawlgalka waa dheer yahay, hababka shaqadu waa adag yihiin, tayada qaybaha dhejinta way adagtahay in la dammaanad qaado. Tusaale ahaan, Feng Liming et al. [8] waxa ay daraasad ku sameeyeen habraac habraaca loogu talagalay dahaadhka nikkel-fosfooraska aan korantada lahayn kaas oo ay ku jiraan oo keliya tillaabooyinka daawaynta sida dereasing, immersion zinc, iyo biyo-dhaqidda oo ku salaysan halabuurka 6063 aluminium aluminium ah. Natiijooyinka tijaabada ah waxay muujinayaan in geeddi-socodku yahay mid fudud, lakabka nikkel-ka elektiroonigga ah wuxuu leeyahay dhalaal sare, xoog isku-xirnaan xoog leh, midab deggan, daahan cufan, maadada fosfooraska ee u dhaxaysa 10% iyo 12%, iyo qallafsanaanta gobolka dahaadhka waxay gaari kartaa in ka badan 500HV. kaas oo aad uga sarreeya kan anodega. Lakabka oksaydh [8]. Marka laga soo tago dahaadhka Ni-P ee aan korantada lahayn, waxa jira alliyaal kale, sida daawaynta Ni-Co-P oo uu bartay Yang Erbing [9]. Filimku wuxuu leeyahay jujuub sare, remanence yar iyo beddelaad koronto oo aad u fiican. Tilmaamaha, waxaa loo isticmaali karaa saxanadaha cufnaanta sare leh iyo meelaha kale, oo leh dahaadh koronto la'aan ah

Habka Ni-Co-P wuxuu heli karaa dhumuc isku mid ah iyo filimka daawaha magnetic on substrate qaab kasta oo adag, oo uu leeyahay faa'iidooyinka dhaqaalaha, isticmaalka tamarta yar iyo hawlgalka ku habboon.

3 dahaarka dusha sare

3.1 Laydhka leysarka

Sanadihii la soo dhaafay, isticmaalka laydhka tamarta sare leh ee loogu talagalay daaweynta laysarka ee dusha aluminium aluminium waxay si wax ku ool ah u wanaajin kartaa adkaanta iyo xidhashada caabbinta aluminium iyo aluminium aluminium. Tusaale ahaan, 5kW CO 2 laser ayaa loo isticmaalaa in lagu dahaadhiyo daahan balasmaha Ni-WC ee dusha sare ee daawaha ZA111. Lakabka fiyuuska leysarka ee la helay wuxuu leeyahay adayg sare, iyo saliidayntiisa, xirashada iyo iska caabbinta abrasion waa 1.75 jeer dahaarka lagu buufiyo iyada oo aan layska daaweynin iyo 2.83 jeer kan Al-Si alloy matrix. Zhao Yong [11] waxay isticmaashay CO 2 lasers aluminium iyo aluminium aluminium substrates

Waxaa lagu dahaadhay daahan budada Y iyo Y-Al, budada waxaa lagu dahaadhay dusha sare ee substrate by habka daahan budada preset, qubeyska laser lagu ilaaliyo by argon, iyo xad gaar ah CaF 2, LiF iyo MgF 2 waa. lagu darey sida walax-samaynta laysarka Marka la eego cabbirada habka laysarka laysarka qaarkood, dahaar cufan oo joogto ah oo leh is-dhexgal bir ah ayaa la heli karaa. Lu Weixin [12] waxay isticmaashay CO 2 laser si ay u diyaariso daahan budada Al-Si, Al-Si + SiC daahan budada ah iyo Al-Si + Al 2 O 3 daahan budada ah ee substrate aluminium aluminium by habka cladding laser. , Al dahaarka budada bronze. Zhang Song iyo al. [13] waxay isticmaashay 2 kW joogto ah ND:YAG laser gudaha AA6 0 6 1 aluminium

Dusha sare ee daawadu waa laysarka laysarka leh ee budada dhoobada ah ee SiC, iyo lakabka dusha sare ee matrix matrix (MMC) oo la beddelay ayaa lagu diyaarin karaa dusha sare ee aluminium aluminium iyada oo loo marayo daaweynta laysarka.

3.2 daahan isku dhafan

Dahaarka isku-dhafka aluminium aluminium-ka-soo-baxa leh ee ka-hortagga-ka-hortagga-ka-hortagga leh iyo guryaha-iska-caabbinta ayaa leh rajooyin codsi oo aad u wanaagsan xagga injineernimada, gaar ahaan dhinaca tignoolajiyada-goynta. Sidaa darteed, xuubabka aluminium ee daloola ee leh qaabdhismeedka matrixka daloolka ayaa sidoo kale ka helay dad badan iyo feejignaan dheeraad ah. Fiiro gaar ah, aluminium aluminium tignoolajiyada isku dhafan ee daahan ayaa noqday mid ka mid ah meelaha cilmi-baarista ee hadda jira. Qu Zhijian [14] waxa uu bartay aluminium iyo 6063 aluminium aluminium aluminium ah oo isku dhafan tignoolajiyada dahaarka is-saliimaynta ah. Habka ugu muhiimsan waa in la sameeyo anodization adag ee aluminium iyo 6063 aluminium aluminium, ka dibna la isticmaalo habka kululaynta kulul si loo soo bandhigo qaybaha PTFE ee daloolada filimka oksaydhka. Iyo dusha sare, ka dib daaweynta kuleylka saxda ah ee vacuum, daahan isku dhafan ayaa la sameeyay. Li Zhenfang [15] waxa uu baadhay hannaan cusub oo isku darka dahaadhka resin-ka iyo habka korantada ee dusha sare ee taayirrada daawaha aluminium ee lagu dabaqo baabuurta. Waqtiga tijaabada CASS waa 66 saacadood, heerka finanku waa ≤3%, heerka dheecaanka naxaasta waa ≤3%, dheelitirnaanta firfircoon waxaa la dhimay 10 ~ 20g, rinjiga resin iyo dahaarka birta ayaa leh muuqaal qurux badan.

4 Hababka kale

4.1 Habka tallaalka Ion

Habka galitaanka ion waxay isticmaashaa alwaaxyada tamarta-sare ee ion si ay u duqeeyaan bartilmaameedka xaalad faaruq ah. Ku dhawaad ion kasta oo la galiyo waa la gaari karaa. Ionyada la geliyo waa dhexdhexaad waxaana looga tagay booska beddelka ama booska farqiga ee xalka adag si loo sameeyo lakab dusha oo aan dheellitirnayn. Aluminium aluminium

Adkaanshaha dusha sare, caabbinta xidhashada iyo iska caabinta daxalka ayaa la hagaajiyay. Magnetron sputtering titanium saafi ah oo ay ku xigto PB11 nitrogen/kaarboon ku dhejinta waxay si weyn u wanaajin kartaa microhardness ee dusha la beddelay. Tuuritaanka Magnetron oo lagu daray duritaanka nitrogen waxay kordhin kartaa adkaanta substrate-ka min 180HV ilaa 281.4HV. Tuuritaanka Magnetron oo lagu daray duritaanka kaarboon waxay kordhin kartaa ilaa 342HV [16]. Magnetron sputtering titanium saafi ah oo ay ku xigto PB11 nitrogen/kaarboon ku dhejinta waxay si weyn u wanaajin kartaa microhardness ee dusha la beddelay. Liao Jiaxuan iyo al. [17] wuxuu sameeyay isku-darka isku-dhafka ah ee titanium, nitrogen, iyo kaarboon oo ku salaysan plazma-ku-salaysan implantation LY12 aluminium aluminium, oo lagu gaadhay saameyn wax-ka-beddelid ah. Zhang Shengtao iyo Huang Zongqing oo ka tirsan Jaamacadda Chongqing [18] waxay sameeyeen tayeynta ion titanium ee daawaha aluminiumka. Natiijooyinku waxay muujiyeen in tallaalka titanium ion ee dusha sare ee aluminium aluminium ay tahay hab wax ku ool ah oo lagu hagaajinayo iska caabbinta chloride ion corrosion, waxayna hagaajin kartaa awoodda aluminium aluminium si ay uga hortagto daxalka chloride ion. Balaadhiya kala duwanaanta suurtogalka ah ee daawaynta aluminium ee NaCl iyo xalalka kale, oo yareeya cufnaanta iyo cabbirka daloolada daxalka ah ee daxaliyay ions koloride.

4.2 daahan beddelka dhulka dhif ah

Dahaarka beddelka naadirka ah ee dusha sare ee dhulka ayaa wanaajin kara iska caabbinta daxalka ee aluminiumyada aluminiumka, iyo geeddi-socodku inta badan waa dhexgalka kiimikada. Dhulka naadirka ah wuxuu faa'iido u leeyahay aluminium aluminium oksidheynta anodic. Waxay wanaajisaa awoodda aluminium aluminium si ay u aqbasho polarization iyo isla mar ahaantaana waxay hagaajinaysaa caabbinta daxalka filimka oksaydhka. Sidaa darteed, dhul dhif ah ayaa loo isticmaalaa in

Daaweynta dusha sare ee aluminiumku waxay leedahay rajo horumarineed oo wanaagsan [19]. Shi Tie iyo al. [20] waxay baratay habka samaynta filimka beddelka milixda cerium ee dusha sare ee aluminium-daxalku-caddaynta LF21 ee kaydinta korantada. Tijaabada orthogonal waxaa loo isticmaalay in lagu barto saameynta arrimaha la xidhiidha habka sameynta filimka iyo cabbirrada farsamada ugu fiican ayaa la helay. Natiijooyinka waxay muujinayaan in habka daxalka anodic ee aluminium-daxalka-caddayn waa la xannibay ka dib markii daawaynta dhigaalka electrolytic ee filimada beddelka dhulka dhif ah, ay iska caabin daxalka si weyn loo hagaajiyo, iyo hydrophilicity ayaa sidoo kale si weyn loo hagaajiyay. Zhu Liping iyo al. [21] loo adeegsaday iskaanka elektaroonigga ah ee microscopy (SEM), spectroscopy energy (EMS) iyo hababka tijaabada buufinta milixda si ay si nidaamsan u daraaseeyaan qaab dhismeedka, halabuurka iyo isafgaradka aluminium alloy naadirka dhulka cerium beddelka milixda ee caabbinta daxalka. Saamayn Natiijooyinka cilmi-baaristu waxay muujinayaan in curiyaha cerium-ka naadirka ah ee filimku uu si wax ku ool ah u joojiyo dabeecadda daxalka ee aluminium aluminium wuxuuna si weyn u wanaajiyaa iska caabbinta daxalka.

Iska caabin daxalka ayaa door muhiim ah ka ciyaara. Maalmahan, waxaa jira habab kala duwan oo daaweynta dusha sare ee aluminium iyo aluminium aluminium ah, shaqadooduna way sii xoogaysanaysaa oo sii xoogaysanaysaa, taas oo buuxin karta baahida aluminium iyo aluminium aluminium ee nolosha, daaweynta caafimaadka, injineernimada, hawada hawada, qalabaynta, qalabka elektarooniga ah, cuntada iyo warshadaha iftiinka, iwm. Loo baahan yahay. Mustaqbalka, daaweynta dusha sare ee aluminium iyo aluminium aluminium waxay noqon doontaa mid sahlan socodka socodka, xasilloonida tayada, baaxad weyn, tamarta-badbaadinta, iyo deegaanka saaxiibtinimo.

Horumarinta jihada. Waa copolymer-ka block ee falcelinta sarrifka ester-amide oo leh heer beddelaad sare. Korshak iyo al. [11] ayaa sheegay in marka 1% PbO 2 ama 2% PbO 2 loo isticmaalo kicinta oo lagu kululeeyo 260 darajo 3-8 saacadood, falcelinta u dhaxaysa polyester iyo polyamide ayaa sidoo kale dhici doonta. Dareen-celinta sarrifka ester-amide waxay saameyn gaar ah ku leedahay iswaafajinta nidaamka isku-dhafka. Xie Xiaolin, Li Ruixia, iwm. [12] iyadoo la isticmaalayo xal

Habka, isku-dhafka fudud ee farsamada (hab dhalaalka 1) iyo joogitaanka habka isku-dhafka falcelinta is-dhaafsiga ester-amide (qaabka dhalaalka) si loo isku daro PET iyo PA66, falanqaynta habaysan ee DSC, iyo waafaqsanaanta nidaamka isku-dhafka PET/PA66 Galmada ayaa laga wada hadlay ilaa xad. Natiijooyinku waxay muujinayaan in nidaamka isku dhafka PET/PA66 uu yahay nidaam heerkulbeeg ah oo aan ku habboonayn, iyo iswaafajinta isku-darka dhalaalka ayaa ka fiican midka isku-dhafka ah ee xalalka, iyo copolymer-ka ay soo saartay isku-dhafka PET/PA66 wuxuu la jaan qaadayaa laba iswaafajinta wajiga. waa la hagaajiyay; kororka maadada PA66, barta dhalaalka ee isku dhafka ayaa hoos u dhacday. PET/PA66 copolymer-ka ay samaysay fal-celintu waxay kordhisaa saamaynta nucleation-ka ee PA66 ee wajiga PET, taasoo keentay dhalaalid Karistalinnimada isku darka faransiiska ayaa ka sarreeya habka dhalaalka 1. Zhu Hong iyo al. [13] loo isticmaalo p-toluenesulfonic acid (TsOH) iyo wakiilada isku xidhka titanate si ay u kiciyaan falcelinta is-dhaafsiga ester-amide ee u dhexeeya Nylon-6 iyo PET si loo gaaro iswaafajinta gudaha ee isku dhafka Nylon-6/PET. Ujeedada natiijada fiirsashada mikroskoob elektarooniga ah ayaa tusinaysa in isku darka Nylon-6/PET uu yahay nidaamka kala soocida wajiga crystalline oo leh iswaafajin liidata. Ku darista p-toluenesulfonic acid iyo wakiilka isku xidhka titanate sida kicinta si kor loogu qaado in-blocking formation Copolymer waxay kordhisaa isku xidhka interface ee u dhexeeya labada weji, ka dhigaysa wejiga kala firdhiyey la safeeyey oo isku mid ah loo qaybiyey, oo waxay caawisaa in la kordhiyo shaqada faafinta dildilaaca ee isku dhafka ah. . Labaduba waxay gacan ka geystaan hagaajinta iswaafajinta isku-dhafka iyo kordhinta ku-dhejinta labada weji ee labada weji.

2 Muuqaalka

Sanadihii la soo dhaafay, cilmi-baarayaasha guduhu waxay sameeyeen shaqo badan oo cilmi baaris ah oo ku saabsan isku-dhafka polyamide / polyester waxayna heleen gabagabo badan oo faa'iido leh, oo aasaas wanaagsan u ah cilmi-baarista mustaqbalka ee aaggan. Waqtigan xaadirka ah, waxa ay tahay in fiiro gaar ah loo yeesho waa in kor loo qaado horumarinta dheeraadka ah ee alaabta isku dhafka ah ee polyamide / polyester iyo in la dabaqo gunaanadkii hore ee dhaqanka wax soo saarka dhabta ah. Marka la beddelo labada, walxo cusub oo ilaalinaysa faa'iidooyinka labada qaybood ayaa la helayaa. Waxay leedahay sifooyin farsamo oo aad u fiican, iska caabbinta biyaha ayaa ka fiican polyamide, iyo adkaanta saameyntu way ka fiican tahay polyesterka. Waxaa si weyn loogu isticmaalaa warshadaha elektiroonigga ah, korontada iyo baabuurta. codsi.

Ku xir maqaalkan : Farsamada Daaweynta Dhulka ee Daawaha Aluminium

Qoraalka Daabacaadda: Haddii aysan jirin tilmaamo gaar ah, dhammaan maqaallada ku yaal boggan waa kuwo asal ah. Fadlan tilmaam halka laga soo daabacayo: https: //www.cncmachiningptj.com/,thanks!

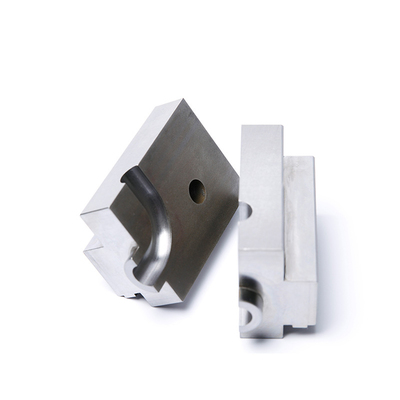

PTJ® waxay bixisaa nooc buuxa oo ah Custom Precision CNC machining Shiinaha adeegyada. ISO 9001: 2015 & AS-9100 shahaado haysta. 3, 4 iyo 5-dhidib sax sax ah Mashiinka CNC adeegyada ay ka mid yihiin shiidida, u jeesashada tilmaamaha macaamiisha, Awoodda qaybaha birta & balaastigga lagu farsameeyo oo leh dulqaad +/- 0.005 mm.dhinta tuurista,bir bir ah iyo xarigBixinta noocyada, noocyada wax soo saarka oo buuxa, taageero farsamo iyo kormeer buuxa.Serves the baabuur, hawada sare, caaryada & qalabka, laydhka hogaaminaya,caafimaadka, baaskiil, iyo macaamil korantada warshadaha. Gaarsiinta waqtiga-Waqtiga ah wax yar nooga sheeg miisaaniyadda mashruucaaga iyo waqtiga la keenayo. Waxaan istiraatiijiyad kula yeelan doonnaa si aan kuu siino adeegyo ugu kharash jaban si aan kaaga caawino inaad gaarto yoolkaaga, Ku soo dhowow nala soo xiriir sales@pintejin.com ) si toos ah mashruucaaga cusub.

PTJ® waxay bixisaa nooc buuxa oo ah Custom Precision CNC machining Shiinaha adeegyada. ISO 9001: 2015 & AS-9100 shahaado haysta. 3, 4 iyo 5-dhidib sax sax ah Mashiinka CNC adeegyada ay ka mid yihiin shiidida, u jeesashada tilmaamaha macaamiisha, Awoodda qaybaha birta & balaastigga lagu farsameeyo oo leh dulqaad +/- 0.005 mm.dhinta tuurista,bir bir ah iyo xarigBixinta noocyada, noocyada wax soo saarka oo buuxa, taageero farsamo iyo kormeer buuxa.Serves the baabuur, hawada sare, caaryada & qalabka, laydhka hogaaminaya,caafimaadka, baaskiil, iyo macaamil korantada warshadaha. Gaarsiinta waqtiga-Waqtiga ah wax yar nooga sheeg miisaaniyadda mashruucaaga iyo waqtiga la keenayo. Waxaan istiraatiijiyad kula yeelan doonnaa si aan kuu siino adeegyo ugu kharash jaban si aan kaaga caawino inaad gaarto yoolkaaga, Ku soo dhowow nala soo xiriir sales@pintejin.com ) si toos ah mashruucaaga cusub.

- 5 Qalabaynta dhidibka

- Qodista Cnc

- CNC leexinta

- Warshadaha Farsamada

- Habka Mashiinka

- Daaweynta dusha sare

- Mashiinnada Birta

- Mashiinka caaga ah

- Caaryada Metallurgy Caar

- Casting Die

- Qaybaha Gallery

- Qaybaha birta otomaatiga ah

- Qalabka Mashiinka

- LED Heatsink

- Dhismaha Qaybaha

- Qaybaha Mobile -ka

- Qaybaha Caafimaadka

- Qaybaha elektarooniga ah

- Mashiinka loogu talagalay

- Qaybaha Baaskiilka

- Mashiinka Aluminium

- Macdanta Titanium

- Machining Steel ahama

- Farsamaynta Naxaasta

- Mashiinka Naxaas

- Mashiinka Daawaha Super

- Mashiinka Feejignaanta

- Mashiinka UHMW

- Farsamaynta Gaarka ah

- PA6 Mashiinka

- Maaraynta PPS

- Mashiinka Teflon

- Mashiinka Inconel

- Qalabaynta Qalabka Birta

- Waxyaabo Badan